- Services

- Field instrument services (Calibration and maintenance)

- Systems Integration

- • Lifecycle Assessment (LCA)

What Capetano offers

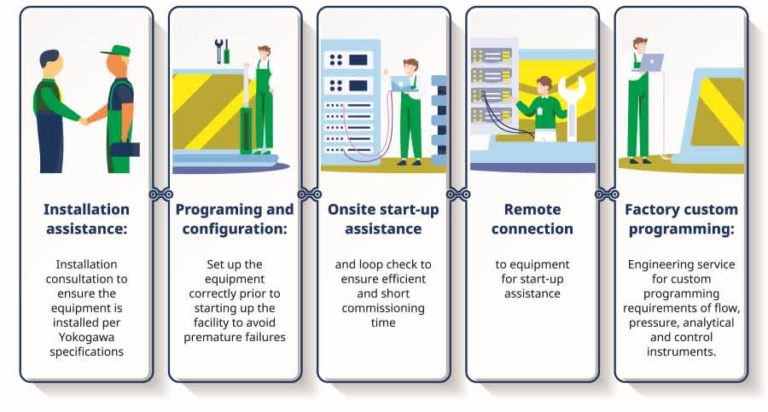

We provide a comprehensive suite of instrumentation / field-services covering calibration, maintenance, repair, commissioning, etc. Some of the key offerings:

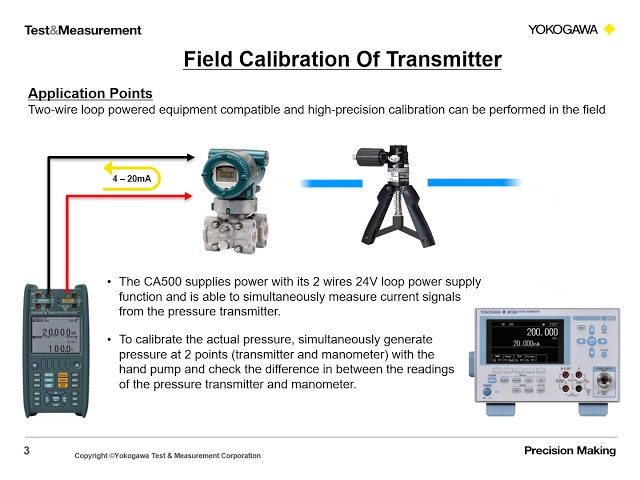

Calibration & certification of instrumentation (pressure, temperature, flow, liquid/gas analysers) including for third-party devices.

Preventative maintenance, corrective maintenance, emergency repair and on-site services.

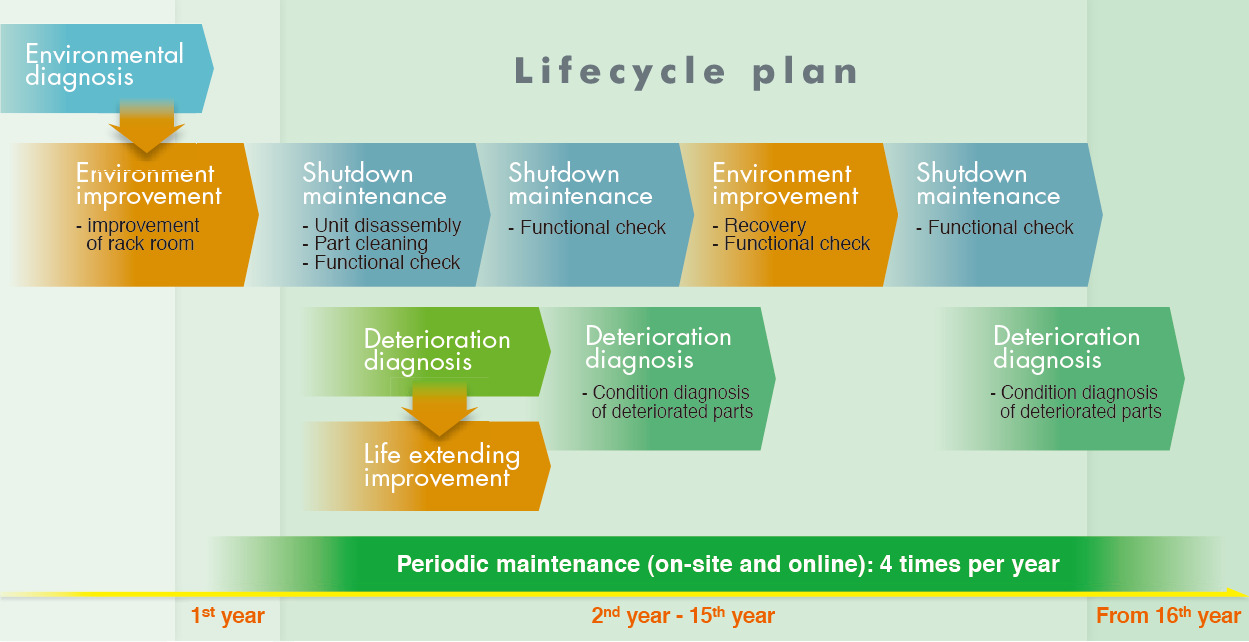

Maintenance & calibration agreements / lifecycle services, which include periodic maintenance, site surveys, calibration visits, spares holding, etc.

Instrument leasing/rotational calibration spares, hot spares, support for older/third-party devices, traceable reference standards.

Capetano — Systems Integration Services

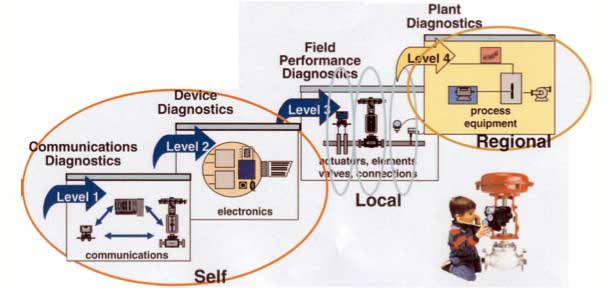

In Yokogawa’s context, systems integration means they act not just as a supplier of instrumentation or control equipment, but as a turn‐key integrator of automation, control, information and sometimes IT/OT systems. Key points:

They provide design, engineering, installation, commissioning and support of large control systems such as their flagship DCS systems (e.g., the CENTUM VP DCS) and related safety/instrumentation networks.

They serve as a “Main Automation Contractor” (MAC) or Main Automation & Information Contractor (MAIC) — meaning they control the full scope of automation + information systems for the plant (engineering, supply, integration) rather than just one box.

Their services include both “greenfield” (new build) and “brownfield” (upgrade/modernisation) projects — e.g., migrating older systems to newer generations.

They integrate not only Yokogawa equipment, but also third-party instrumentation and systems, and interface with IT/cloud/IIoT domains. For example: their “Collaborative Information Server” supports integration of devices, plant systems, cloud.

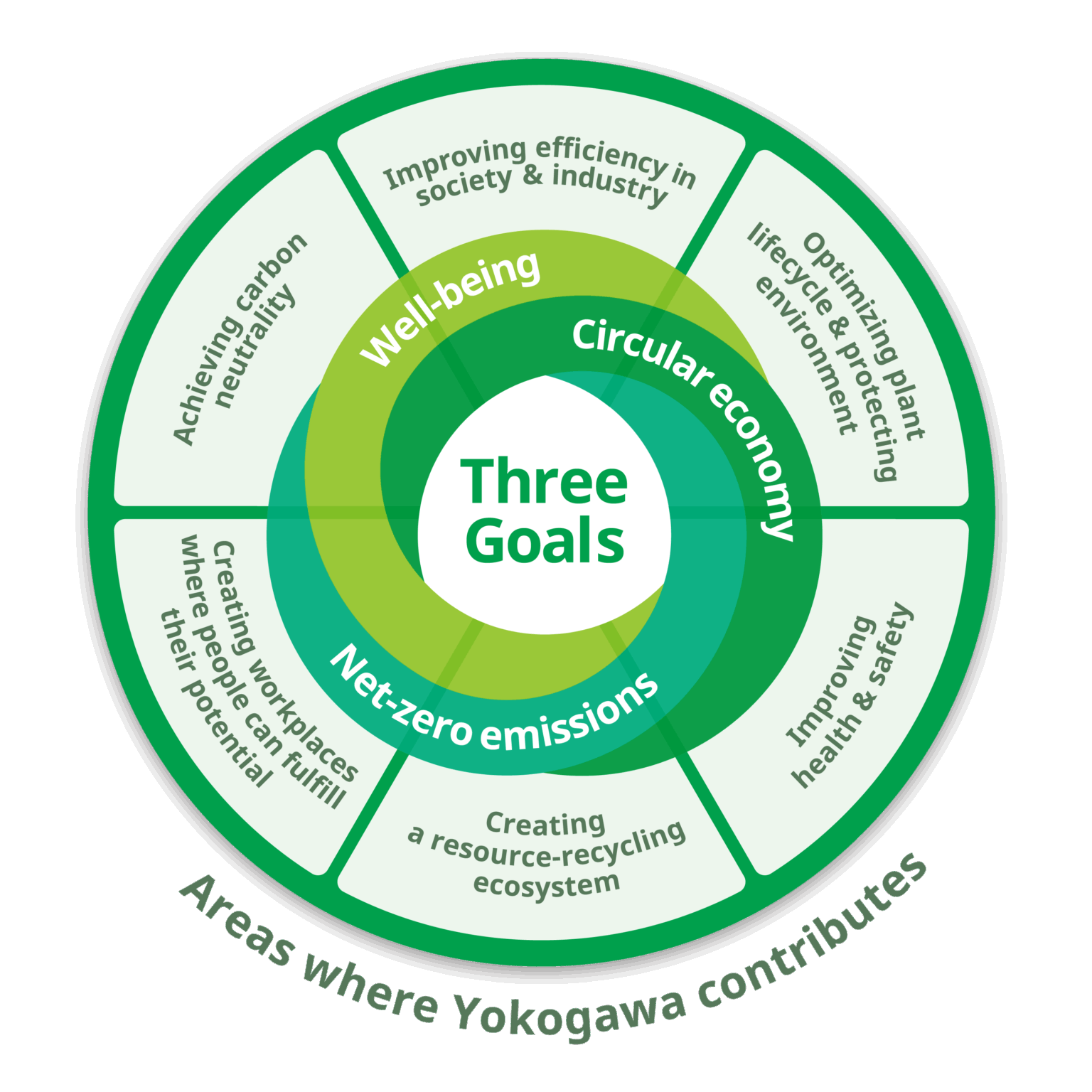

What Yokogawa Means by LCA?

Yokogawa began conducting Life Cycle Assessments (LCA) in the design phase of all new products since around 1999, aiming to reduce environmental impact.

Their LCA standards cover major environmental-impact indicators, such as energy use, CO₂, NOₓ, SOₓ emissions across a product’s lifecycle.

As part of their sustainability commitment “Trusted Green”, Yokogawa emphasises lifecycle thinking: from planning → procurement → manufacturing → use → service → recycling.

Key Elements of the LCA Approach

Product design & assessment criteria: They have developed assessment standards in eight areas: recyclability/treatment, resource conservation, energy conservation, long-term usability, ease of collection & transport, safety & environmental protectiveness, information disclosure, packaging.

LCA labelling: Products for which Yokogawa has conducted LCA under its standard and disclosed the results are given an “LCA label”.

Comparison basis: For assessment, Yokogawa often compares a new product to a previous product (same or similar functionality) to show improvements (e.g., reduction in CO₂ emissions).

Lifecycle span: Their approach considers raw material procurement, manufacturing, transport, use/operation at customer site, maintenance/service, and end-of-life (recycling/disposal) stages.

Feel free to dop us a line

Contact us for further enquiries:

Office Location:

Capetano Oil Ltd., 2nd Osu Badu Street Airport Residential Dzorwulu Accra

- Tel: +233535191114

- Email: engineers@capetano.com