- Products

- • Field Instruments (Pressure Transmitters, Flowmeters, Temperature Transmitters, Level meters, Field wireless, Device Smart Communicators, Fiber Optic, Temperature Sensor DTSX, Current to Pneumatic converter, Pressure Calibrators, Valve Manifolds)

- • Test & Measurement (Oscilloscopes, Power Analyzers & Power meters, Data Acquisition, Optical Test Equipment, Signal Generators, Signal sources, signal supplies, Pressure measurement instruments, other test & measurement instruments, accessories, Portable & handheld instruments)

- • Automation and control systems {Distributed Control Systems (DCS), }

- • Safety Systems {Safety Instrumented systems (SIS)}

- • Internet of Things (IoT) – enabled monitoring

Test & Measurement

Overview of test & measurement equipment from Yokogawa (Test & Measurement division) — including their product scope, strengths, and examples of flagship instruments suitable for serious lab/industrial use.

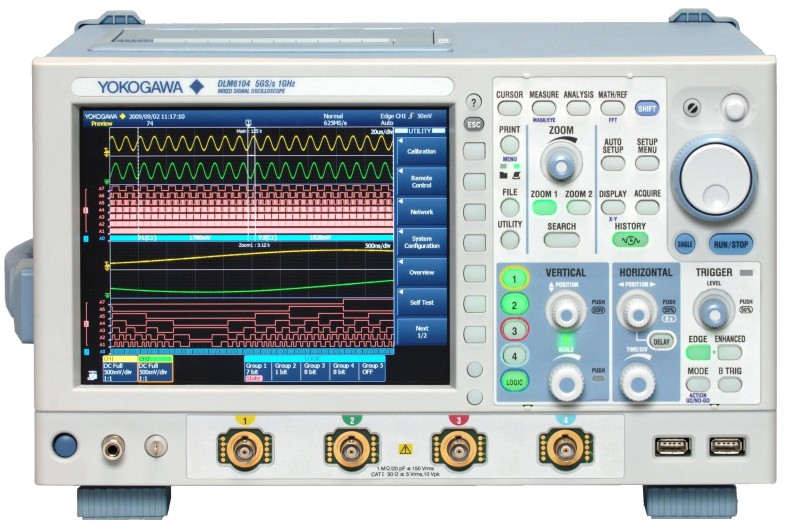

Oscilloscopes & ScopeCorders

High-speed digital oscilloscopes & mixed-signal models (for debug/R&D) – see their “Digital Oscilloscopes” section. Yokogawa

ScopeCorder units: combine oscilloscope + multi-channel data recorder for long-term capture. Yokogawa

Applications: electronics circuit debug, power electronics switching behaviour, mixed-signal systems, long-term capture of multiple channels.

Power Analyzers & Power Meters

- Yokogawa states they are “the world’s largest manufacturer of energy and power analyzers and meters”. Yokogawa TMI+1

- These instruments deliver accuracy in watts, power factor, harmonics, efficiency. Excellent for EV inverter testing, motor drives, grid‐tie systems.

- Example series: WT5000, WT3000, PX8000 (power scope) in their catalog.

Data Acquisition (DAQ) & Recorder Systems

For capturing many channels of analog/digital data, recording over time.

Particularly relevant for automotive, mechatronics, power electronics test.

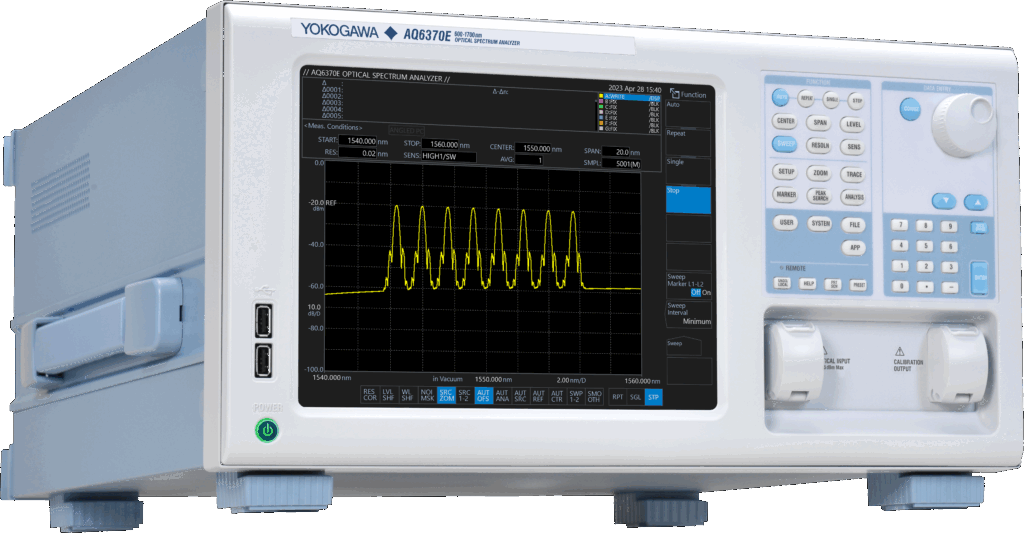

Optical Test Equipment

- Covering fiber-optics, lasers, optical components: spectrum analyzers, OTDRs, optical power meters. Yokogawa

- Useful for telecom/optical R&D, production, network test.

Signal Generators, Sources & Supplies

- Signal sources for stimulus in test setups, function generators, source-measure units. Yokogawa

- Applicable when you need precise waveform generation, stimulus or source supply for DUT.

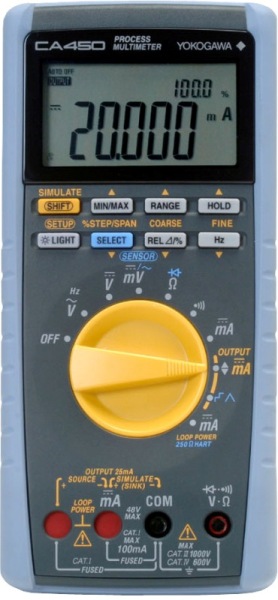

Portable & Handheld Instruments

- Field measurement gear: multimeters, clamp meters, handheld power meters, pressure calibrators.

- Good for service/maintenance, calibration labs, portable work. Catalog shows many such tools.

Automation and control systems {Distributed Control Systems (DCS)

Overview

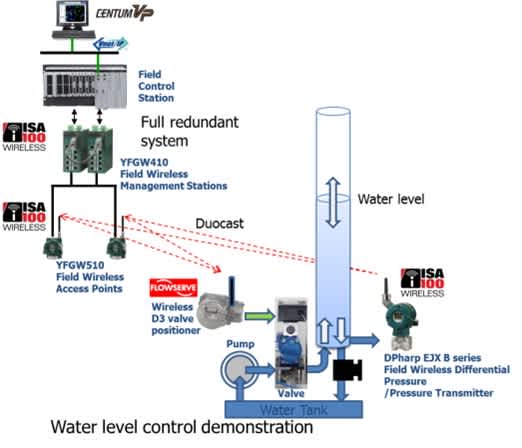

Yokogawa’s DCS solutions provide automation and control platforms for large-scale industrial plants (oil & gas, petrochemical, power, water/wastewater, chemicals, etc.). Their flagship system is the CENTUM VP series (part of the OpreX Control and Safety System family). Yokogawa+2Automation.com+2

Key points:

A DCS (Distributed Control System) decentralises control: controllers and I/O nodes are distributed throughout the plant, rather than all control being in one central unit. Yokogawa+1

Yokogawa introduced the original CENTUM DCS in 1975 and today it is in its 10th generation. Control Design+1

Their system supports continuous operations, high availability, and integration of control, safety and information layers. Yokogawa+1

Key Features & Benefits

Here are some of the standout features of Yokogawa’s DCS solutions:

Separation of operator interface and controllers: If the HMI (Human‐Machine Interface) fails, the controller continues managing the process, enhancing reliability.

Decentralised installation of I/O and controllers: Field nodes can be placed closer to process equipment, reducing wiring and improving maintainability.

High system availability and fault tolerance: Controllers and partitions can fail without taking down the entire system. Yokogawa+1

Backward compatibility & migration support: Yokogawa emphasizes that upgrades are designed to preserve investment and minimise downtime.

Standards compliance and cyber-security: Supports ISA/IEC standards like ISA-18.2 (alarm management), ISA-95 (enterprise control integration), ISA-99/IEC 62443 (cybersecurity) among others.

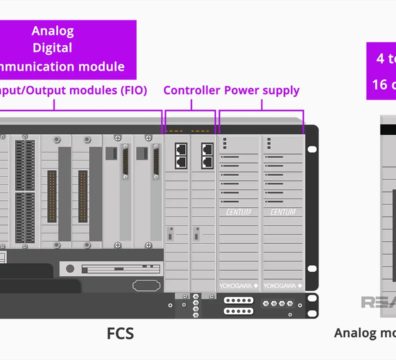

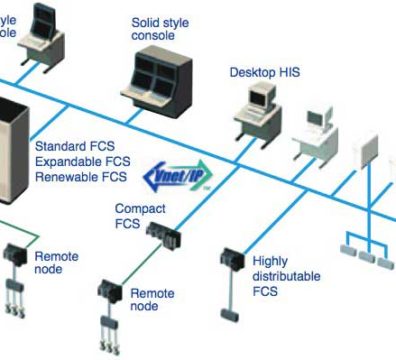

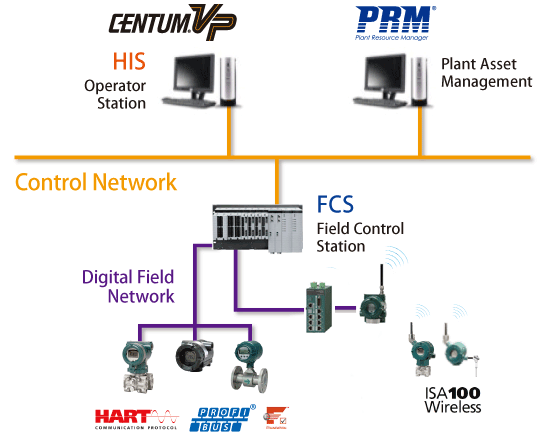

Typical Solution Architecture

The architecture of a Yokogawa DCS system typically involves:

Field devices and I/O modules distributed across the plant.

Control stations/controllers (often dual redundant) performing real-time control.

A high-speed control network (for example, Yokogawa’s Vnet/IP) linking controllers, I/O and HMIs.

Operator stations/HMIs for monitoring & control.

Integration with enterprise systems, historical databases, batch systems, safety systems.

Tools for engineering, diagnostics and maintenance.

Product & System Offerings

Some of the relevant offerings include:

CENTUM VP Series: Yokogawa’s current flagship DCS product line. Yokogawa+1

Migration solutions for upgrading older DCS systems (including earlier CENTUM variants) to the newer platform, with minimal downtime.

Related modules: alarming/condition monitoring, field instrument management, batch control, safety instrumented systems (SIS) integrated with the DCS.

Capetano

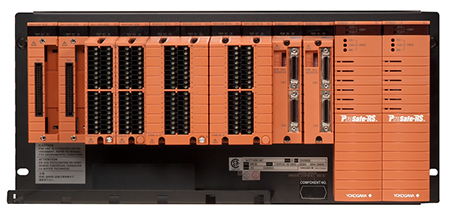

Safety Systems {Safety Instrumented systems (SIS)

A Safety Instrumented System (SIS) is a dedicated system whose role is to detect abnormal conditions, intervene, and bring the process to a safe state. In other words, while the process control system (DCS / PLC) handles normal operations, the SIS acts as a protection layer for humans, assets and the environment.

Why it matters:

For industrial plants in oil & gas, petrochemical, power, terminals, etc., risk of major incidents (fire, explosion, overpressure, toxic release) is real. The SIS is a key layer of protection.

Regulatory compliance: Many jurisdictions require SIL-rated safety systems and documented lifecycle management.

Integration benefits: A well-designed SIS can integrate with the control system (DCS) but still maintain independence for safety. Yokogawa emphasises this balance.

Typical Applications

Typical Applications

Yokogawa’s SIS solutions are applied in:

Emergency Shutdown (ESD) Systems: automatically shut down plant/process when predefined unsafe condition occurs.

Fire & Gas (F&G) Systems: detection and mitigation of fire, gas leak scenarios. Yokogawa+1

Burner Management Systems (BMS): for incinerators, boilers, furnaces — ensuring safe start/stop and shut-off in unsafe conditions.

High Integrity Pressure Protection Systems (HIPPS): relevant in pipeline, subsea, chemical plants to prevent overpressure incidents.

Integration with larger “Integrated Control & Safety Systems” (ICSS) architectures: SIS + DCS + instrumentation in unified environment.

Capetano

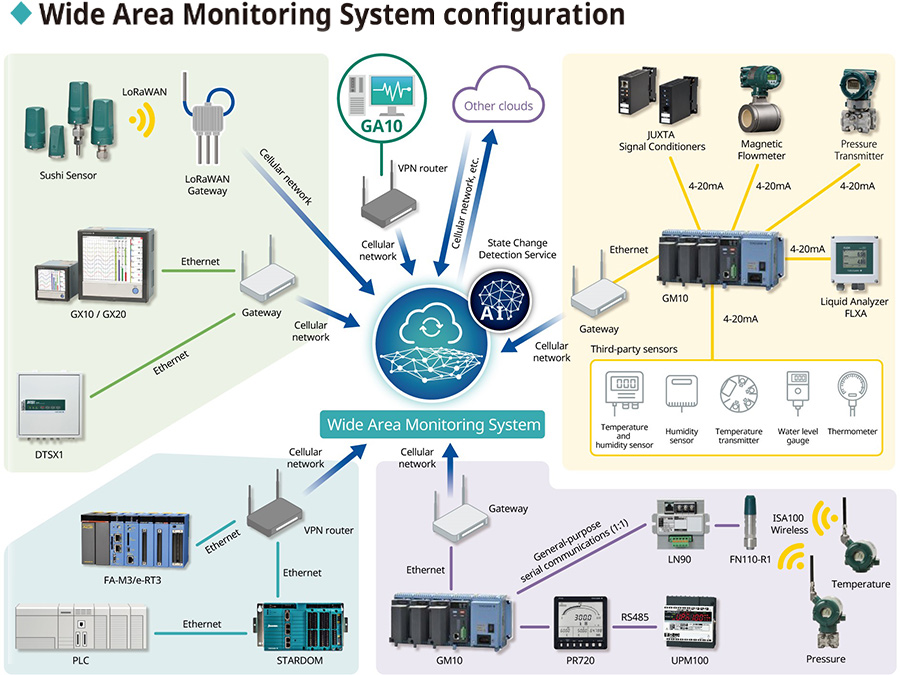

Internet of Things (IoT) – enabled monitoring

What this means & Why it matters

What this means & Why it matters

“IoT/IIoT-enabled monitoring” refers to remote, networked sensing and analytics of assets/equipment, often via wireless sensors + gateways + cloud or local servers.

For Yokogawa, the goal is to move from reactive or scheduled maintenance toward condition-based monitoring and predictive maintenance, improving uptime, reducing unplanned shutdowns, and optimising maintenance cost.

With distributed facilities (plants, remote sites, large footprint), traditional wired measurements are often impractical. Wireless/IoT solutions help cover wide areas, harsh environments, and gather data for analytics.

This kind of monitoring is of growing importance in African markets (mining, oil & gas, utilities) where remote assets and wide-area operations are common.

Typical Use-Cases & Benefits

Typical Use-Cases & Benefits

Remote asset health monitoring: instead of manual rounds, sensors continuously monitor equipment condition and send alerts early when signs of degradation appear. (E.g., steam traps, pumps, rotating equipment) Yokogawa+1

Wide‐distributed facility monitoring: For example, pipeline pressure monitoring across remote sites or remote water supply monitoring; remote equipment spread over large geography.

Condition-based maintenance (CBM) and predictive maintenance: By trending sensor data (vibration, temperature) and applying analytics, you can catch problems before failure.

Energy/efficiency optimisation: Monitoring steam traps, leaks, etc., helps reduce waste (e.g., GHG emissions) and improves operational cost.

Data-driven decision-making: By capturing more data and making it visible to maintenance, operations, management, you improve decision making (what to service, when).